Agriculture

Agriculture- Soil and fertilizer

Building

Building- Building materials

- Sanitary faucets

- Sanitary valves

Chemical

Chemical Food & Beverages

Food & Beverages- Food and edible

- Food industry

- Nuts & dried fruit

- sweets

- tomato paste

Handicrafts

Handicrafts- Gabbeh Glim Carpet

- Mina & Khatam

- penmanship

Home & kitchen

Home & kitchen- Furniture

Industry

Industry- Metals

- Refractory

Mineral

Mineral Oil and gas

Oil and gas Other

Other Petrochemical

Petrochemical- Digital goods

- Information storage equipment

- International SSD memory

- Flash memory

- Memory card

- Computer and accessories

- International hard drive

- International hard drive

- Laptop

- Laptop

- Camera

- Photography accessories and filmmaking

- Mobile

- Headphones, headsets and handsfree

- Sports & Travel

- Men ‘s

- Automotive Fuel and Oil Supplements

- Aerobic and fitness sports

- Home & Kitchen

- Automobiles & Motorcycles

- Automotive Consumables

- Automotive Oil & Antifreeze

- Engine Oil

- Antifreeze & Water Radiator

- Automotive Filter

- Oil Filter

- Fuel Filter

- Air Filter

- Beauty & Health

- Electrical Personal Appliances

- Hairdryer

- Digital Goods

- Camera

- Electrical Home Appliances

- Washing & Cleaning Supplies

- Sweeping Cordless

- Fashion & Apparel

- Female & Male

- Women’s & Men’s Shoes

- Women’s & Men’s Sneakers

- Pets

- Men’s Slippers

- Men’s Sandals

- Bird food and seeds

- Animal Food & Supplements

- Nest and cage for keeping animals

- Bird food

- Dog Food

- Cat Food

- Dry cat food

- Malt & Cat Strengthening Supplement

- Sports Thermos & Shaker

- Thermoses, Flasks and Colemans

- Men’s Shoes

- Mobile Phone

- Travel & Camping Supplies

- Camping Supplies

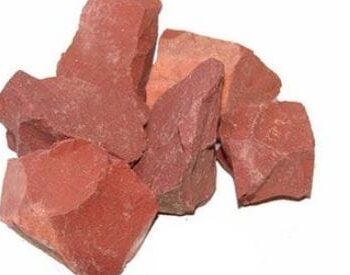

Iron Oxide for Casting

Brand

Brand

|

Various brands |

|---|---|

Packing

Packing

|

Negotiable |

Color

Color

|

Like the Picture |

Size

Size

|

Various sizes |

Type of sale

Type of sale

|

|

Origin

Origin

|

|

Minimum Order

Minimum Order

|

Negotiable |

5

Items sold in last 3 months

2

People watching this product now!

SKU:

ironOxide_casting

Categories: Industry, Mineral

Tags: carbon reduction, casting, defect prevention, increased resistance, iron oxide, iron parts production, quality improvement, smelting industry, steel parts

Brand: Various brands

Description

Iron Oxide for Casting

Iron oxide for casting is one of the essential raw materials in the smelting and casting industry. With the chemical formula Fe2O3 and a gray or black color, it is widely used in the production of iron and steel parts. Iron oxide helps reduce carbon uptake, prevent casting defects such as streaks and alligator skin, and increase resistance to melt penetration. Additionally, the use of this material enhances the quality and durability of the produced parts.

Features and Benefits:

- Carbon Reduction: Iron oxide helps reduce the carbon content in cast parts.

- Defect Prevention: This material prevents the formation of streaks and alligator skin in cast parts.

- Increased Resistance: The use of iron oxide increases the resistance of parts to melt penetration and other damaging factors.

- Quality Improvement: This material helps improve the quality and durability of iron and steel parts.

Applications:

- Casting Industry: Iron oxide is widely used in the production of iron and steel parts.

- Smelting Industry: This material plays a crucial role in smelting processes and metal production.

Keywords: iron oxide, casting, carbon reduction, defect prevention, increased resistance, quality improvement, smelting industry, iron parts production, steel parts

اکسید آهن به کاهش جذب کربن، جلوگیری از عیوب ریخته گری مانند رگه ها و پوست تمساح و افزایش مقاومت در برابر نفوذ مذاب کمک می کند.

Add information

- The import of this product may include customs regulations in the destination country.

- The prices of the product are in the form of delivery to the Exwork.

- For more information, please send an inquiry.

Be the first to review “ Iron Oxide for Casting” Cancel reply

Agriculture

Agriculture Building

Building Chemical

Chemical Food & Beverages

Food & Beverages Handicrafts

Handicrafts Home & kitchen

Home & kitchen Industry

Industry Mineral

Mineral Oil and gas

Oil and gas Other

Other Petrochemical

Petrochemical

Reviews

There are no reviews yet.